| Sign In | Join Free | My gastesters.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My gastesters.com |

|

Brand Name : GWELL

Model Number : GWS90/GWS120/GWS130

Certification : CE

Place of Origin : China

MOQ : 1 set

Price : Negotiable

Payment Terms : L/C, T/T

Supply Ability : 1 set per 90 days

Delivery Time : 90 days

Packaging Details : STRETCHING FILM, PLASTIC FILM PACKAGE, WOODEN CASES PACKAGE FOR KEY PARTS

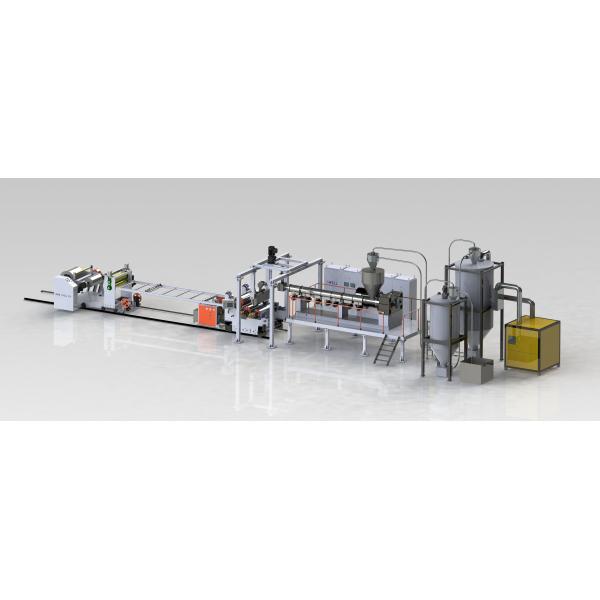

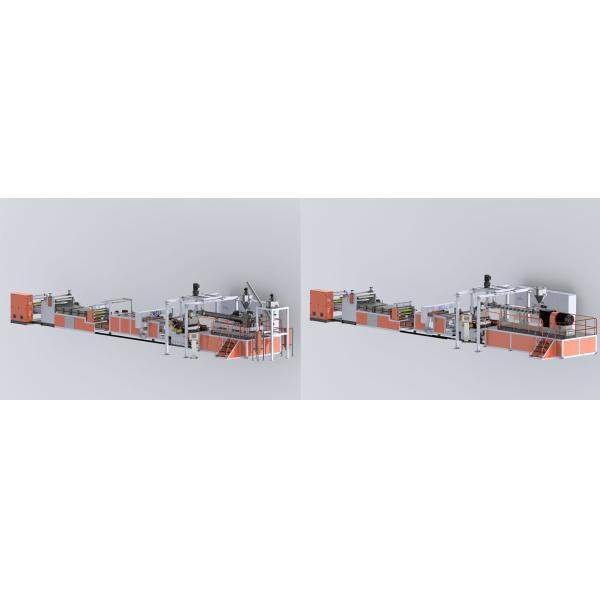

Product name : PET Blister Sheet Extrusion Machine PET Transparent Sheet Machine Can Be Designed Independently

Brand : GWELL

Country of origin : China

Suitable material : virgin PET, recycled PET, PET flakes, PET scraps

Width : 800-1500mm

Thickness : 0.2-1.5mm

Screw design : single screw / parallel twin screw

Product application : food container,food box,transparent cake box, etc

Sheet structure : one layer,two layers, three layers, multiple layers

Color of sheet : transparent, colored

Warranty : One year

After-sale service : installation and machine debug

PET Blister Sheet Extrusion Machine PET Transparent Sheet Machine Can Be Designed Independently

Gwell PET Blister Sheet Extrusion Machine is company's strategic continuous improvement model. As to this equipment, company adopts the special sales model to ensure the first market share, the lowest price for the same parameter configuration, and the first echelon of PET Blister Sheet Extrusion Machine. The raw materials can be APET, PETG, PET Blister Sheet Extrusion Machine

Classification of PET Blister Sheet Extrusion Machine:

1. Single screw production line for PET sheet: single screw extrusion production line for PET Blister Sheet Extrusion Machine project with the most stable production at present. Generally, single extruder production line or twin-extruder production line is adopted and Gwell uses the latest technology to increase the general efficiency by 30%.

2. PET Blister Sheet Extrusion Machine: this machine only needs to crystallize PET Blister Sheet Extrusion Machine. Its advantages: low energy consumption, simple process, convenient equipment maintenance, and can ensure the blister 18CM deep cup.

3. PET Blister Sheet Extrusion Machine (free from crystallization and drying) : the planetary screw extruder is adopted as the main machine to increase the space for materials and air, and with the vacuum pumping system newly developed by Gwell can meet the needs of customers with large output and high quality sheets.

| Type of extrusion line | single screw sheet PET extrusion line | single screw venting sheet PET extrusion line | twin screw venting PET sheet extrusion line | PET sheet planetary multi-screw exhaust extrusion line |

| Method of dealing material | Crystallization and drying | Free from crystallization and drying | Free from crystallization and drying | Free from crystallization and drying |

| Structure of Product | Single layer, double-layer or multi-layer PET sheet | |||

| Width of Product | 600mm-1220mm | |||

| Thickness of Product | 0.17mm-2mm | |||

| Output | 200kg/h-1200kg/h | |||

Revolutionize Your Production with GWELL’s High-Performance PET Sheet Extrusion Line!

GWELL delivers cutting-edge PET sheet extrusion lines engineered for maximum efficiency, precision, and sustainability. Ideal for producing APET, RPET, CPET, and PET-G sheets, our extrusion technology sets new industry benchmarks:

✅ Turnkey Solutions – From installation to after-sales support

✅ Global Installations – Trusted by 500+ clients across 30+ countries

✅ Fast ROI – High yield and low waste maximize profitability

Ready to Boost Your Production?

Contact Our Experts Today!

Liam

saled@gwell.cn | +86 15906224102

Max

salem@gwell.cn | +86 15906227399

Explore more at [GWELL Website]: www.gwellmachine.com

Option 1 (Concise & Benefit-Focused):

Unlock Solar Film Production Flexibility | GWELL Co-Extrusion Line

Maximize your PV module encapsulant output with GWELL's advanced co-extrusion line. Engineered for high-performance EVA, POE, and EPE solar films, our technology delivers precision thickness control, blistering speeds, and unmatched reliability. Boost productivity & quality for superior module encapsulation.

Option 2 (Solution-Oriented & Keyword Rich):

GWELL EVA/POE/EPE Solar Film Co-Extrusion Line: Your All-in-One Solution

Streamline production of high-quality PV module encapsulation films (EVA, POE, EPE) with GWELL's innovative co-extrusion line. Achieve exceptional layer adhesion, precise gauge control, and high throughput while reducing operational costs. Engineered for dependable, automated solar film manufacturing.

Option 3 (Feature Highlighting & Technology Focus):

Cutting-Edge Co-Extrusion for Premium Solar Encapsulation | GWELL

The GWELL EVA/POE/EPE Co-Extrusion Line sets the standard for producing multi-layer encapsulant films critical for durable, high-efficiency solar panels. Featuring automatic gauge control, optimized melt homogeneity, integrated cooling & winding, it ensures consistent perfection for EVA, POE, or EPE formulations.

Option 4 (Benefit-Driven & Audience Focused):

Empower Your Solar Film Production with GWELL Co-Extrusion

Meet soaring demand for EVA, POE, and EPE encapsulation films. GWELL's co-extrusion line provides reliable, high-volume production of defect-free films with superior surface quality and UV stability. Achieve lower production costs & faster time-to-market. Scale your PV supply chain efficiently.

Why Choose GWELL?

✅ Turnkey Solutions – From installation to after-sales support

✅ Global Installations – Trusted by 500+ clients across 30+ countries

✅ Fast ROI – High yield and low waste maximize profitability

Ready to Boost Your Production?

Contact Our Experts Today!

Liam: saled@gwell.cn | +86 15906224102

Max:salem@gwell.cn | +86 15906227399

Explore more at [GWELL Website]: www.gwellmachine.com

Revolutionize Your Production with GWELL’s High-Performance PET Sheet Extrusion Line!

GWELL delivers cutting-edge PET sheet extrusion lines engineered for maximum efficiency, precision, and sustainability. Ideal for producing APET, RPET, CPET, and PET-G sheets, our extrusion technology sets new industry benchmarks:

✅ Turnkey Solutions – From installation to after-sales support

✅ Global Installations – Trusted by 500+ clients across 30+ countries

✅ Fast ROI – High yield and low waste maximize profitability

Ready to Boost Your Production?

Contact Our Experts Today!

Liam

saled@gwell.cn | +86 15906224102

Max

salem@gwell.cn | +86 15906227399

Explore more at [GWELL Website]: www.gwellmachine.com

Option 1 (Concise & Benefit-Focused):

Unlock Solar Film Production Flexibility | GWELL Co-Extrusion Line

Maximize your PV module encapsulant output with GWELL's advanced co-extrusion line. Engineered for high-performance EVA, POE, and EPE solar films, our technology delivers precision thickness control, blistering speeds, and unmatched reliability. Boost productivity & quality for superior module encapsulation.

Option 2 (Solution-Oriented & Keyword Rich):

GWELL EVA/POE/EPE Solar Film Co-Extrusion Line: Your All-in-One Solution

Streamline production of high-quality PV module encapsulation films (EVA, POE, EPE) with GWELL's innovative co-extrusion line. Achieve exceptional layer adhesion, precise gauge control, and high throughput while reducing operational costs. Engineered for dependable, automated solar film manufacturing.

Option 3 (Feature Highlighting & Technology Focus):

Cutting-Edge Co-Extrusion for Premium Solar Encapsulation | GWELL

The GWELL EVA/POE/EPE Co-Extrusion Line sets the standard for producing multi-layer encapsulant films critical for durable, high-efficiency solar panels. Featuring automatic gauge control, optimized melt homogeneity, integrated cooling & winding, it ensures consistent perfection for EVA, POE, or EPE formulations.

Option 4 (Benefit-Driven & Audience Focused):

Empower Your Solar Film Production with GWELL Co-Extrusion

Meet soaring demand for EVA, POE, and EPE encapsulation films. GWELL's co-extrusion line provides reliable, high-volume production of defect-free films with superior surface quality and UV stability. Achieve lower production costs & faster time-to-market. Scale your PV supply chain efficiently.

Why Choose GWELL?

✅ Turnkey Solutions – From installation to after-sales support

✅ Global Installations – Trusted by 500+ clients across 30+ countries

✅ Fast ROI – High yield and low waste maximize profitability

Ready to Boost Your Production?

Contact Our Experts Today!

Liam: saled@gwell.cn | +86 15906224102

Max:salem@gwell.cn | +86 15906227399

Explore more at [GWELL Website]: www.gwellmachine.com

|

|

0.2 - 1.5mm PET Blister Sheet Extrusion Machine PET Transparent Sheet Machine Images |